1922

In 1922, Fritz von Opel was the successful pilot of the Bahnrennmaschine, an early-model motorcycle. Constructed from extremely lightweight materials, it weighed just 69 kilograms. However, we wouldn’t recommend trying to ride one yourself because the designers left out a transmission, clutch, and brakes. Parts of the engine, the pistons, and the crank case were made of magnesium.

1928

The Motoclub 500 hit the market in 1928. The frame was atube structure composed of sheet steel, making it lighter than all previous models. Another lightweight construction characteristic of this vehicle was its aluminum pistons.

1935

The Olympia revolutionized carmaking in 1935. It was the first vehicle with a self-supporting full steel chassis to be mass-produced in Germany. That helped to reduce its weight to 835 kilograms. The Olympia was 135 kilograms lighter than its predecessor with the same level of engine performance.

1981

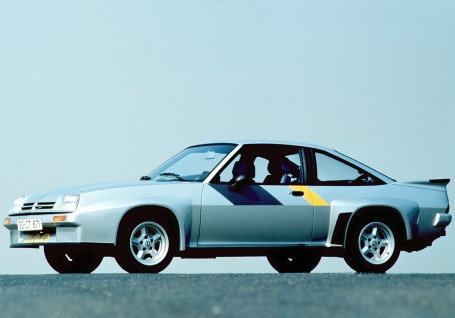

Since the very beginning, lightweight construction has been an important issue in the world of motor racing. One example is the Manta 400 from 1981. The implementation of new construction materials was what primarily reduced the weight of this model in comparison to the Ascona 400 by just under 80 kilograms. The front, doors, and trunk lid were composed of plastic, and coated plastic replaced glass in the windows and rear windshield (but not the front windshield). Additionally, Opel tested carbon fiber-reinforced rear axle tubes, drive shafts, and other small components in this model.

1995

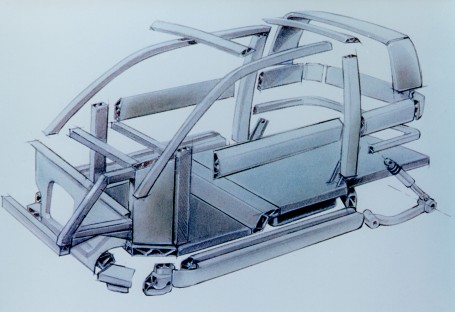

The MAXX, which was introduced as a concept at the 1995 Geneva Motor Show, weighed just 650 kilograms. The body was composed of extruded aluminum profiles, the chassis primarily of aluminum, the camshafts were molded to be hollow, and the wheels were made of magnesium. The aluminum components used were attached with screws, making them easy to recycle.

1997

Lightweight construction was a consistent goal with the Sintra in 1997. Because it was constructed using high-strength steel, aluminum, and magnesium, its most basic model weighed in at just 1,620 kilograms, making it one of the lightest vans on the market at the time. The hood, heat protection shield, front seat rails, parking brake, and the rim of the spare tire were all made of aluminum, as were the chassis components such as the rims, steering knuckle, main brake actuator, engine bracket, and tie rod ends. Even lighter magnesium was used to make the seat rails, steering wheel, steering column, and pedal assembly. The payoff: Lower fuel consumption and a car that handles like a sedan.

1999

Releasing just 90 grams of CO² emissions per kilometer, the concept vehicle G90 was considered futuristic when it debuted in 1999. Thanks to Opel’s intelligent implementation of aluminum and magnesium, the four meter-long car weighed in at just 750 kilograms. And the engineers cleverly managed to use this lightweight design to implement other helpful innovations. The vehicle’s low fuel consumption meant it could get away with a smaller gas tank, and its low overall weight meant that the brake construction could be lighter. All of the chassis components were designed to be light. The body was made of aluminum, as were heavy-wear parts like the steering knuckle and struts. Stainless steel lowered the weight of the exhaust system. Moreover, ultra-light magnesium was used for the transmission casing, steering wheel, seat components, hatch, and even the roof.

With the Astra Eco 4, Opel presented a mass-produced vehicle with intelligent lightweight construction at the 1999 IAA. In addition to aluminum and magnesium, the company increasingly implemented high-strength steels and laser-welded sheet metal plates of varying strengths. Opel also made use of innovative production methods such as hydroforming, where components are shaped using water. The model weighed just 1,140 kilograms.

2000

The Speedster was a true highlight in terms of lightweight construction. It was the first mass-produced Opel with an aluminum chassis and a plastic body. The body was composed of 25 individual components made of fiberglass-reinforced plastic. The frame consisted of extruded aluminum profiles that were stuck together. It was held together by a shell made of fiberglass-reinforced plastic. The chassis weighed just 60 kilograms. The engine was made of aluminum, which was also primarily used in the car’s interior.

2002

Light, high-strength materials were used to construct the Vectra C, which hit the market in 2002. They included boron-alloyed steels, magnesium, and aluminum. The aluminum hood, for instance, was 45 percent lighter than a conventional hood made of sheet steel. Magnesium also made many of the components significantly lighter, including the dashboard crossmember.