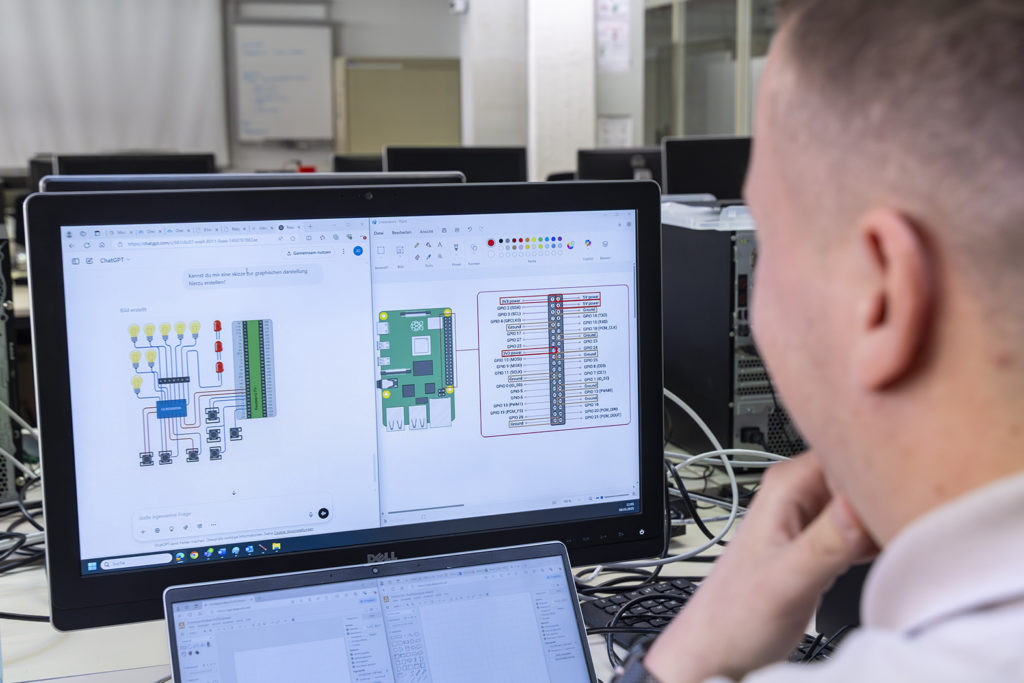

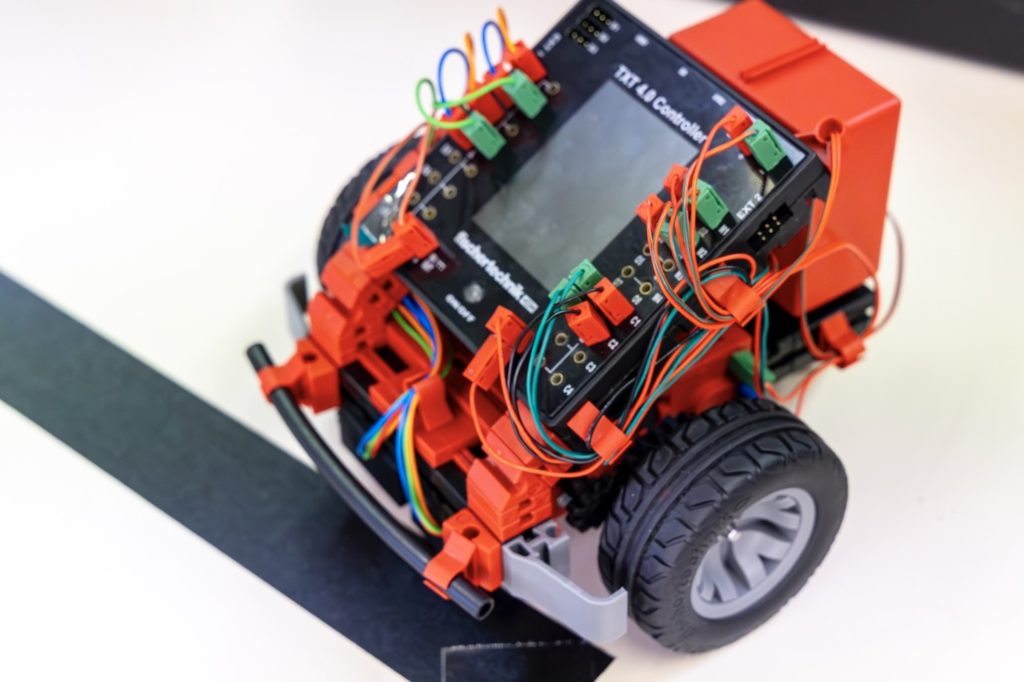

Placing the central unit, connecting cables, testing circuits: Esther Fink is working on a programmable logic controller – the nerve centre of automation. It controls robots and systems. “Signals are converted into actions,” she says. She wrote the program for this herself. She has been training at Opel for six months: mechatronics technician in training, at the same time a student in engineering. She can also weld. “I can do a proper seam.”

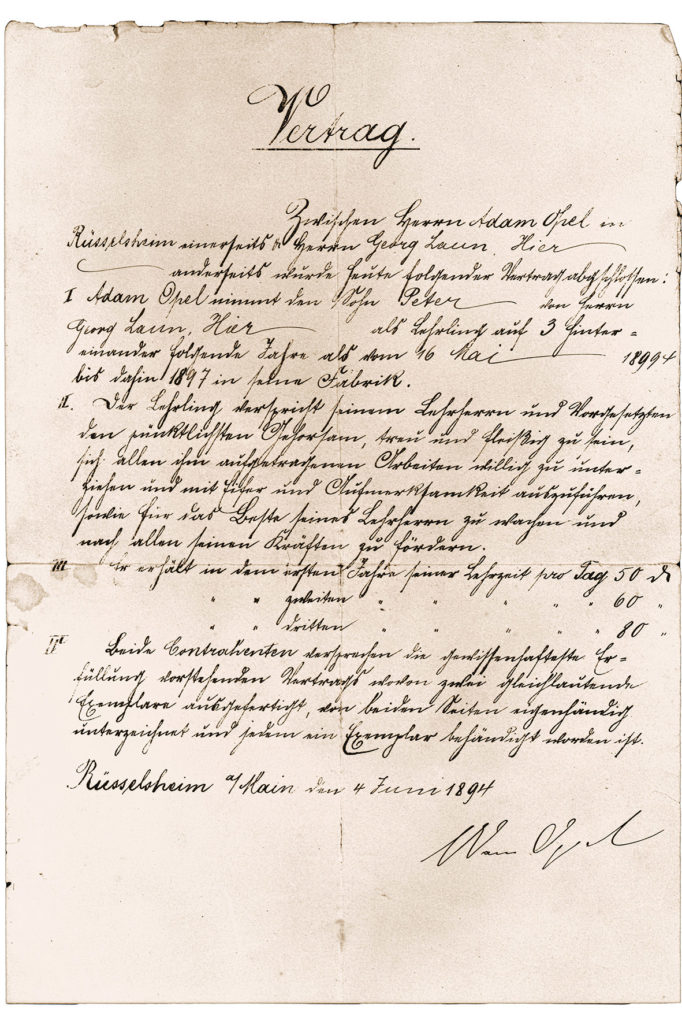

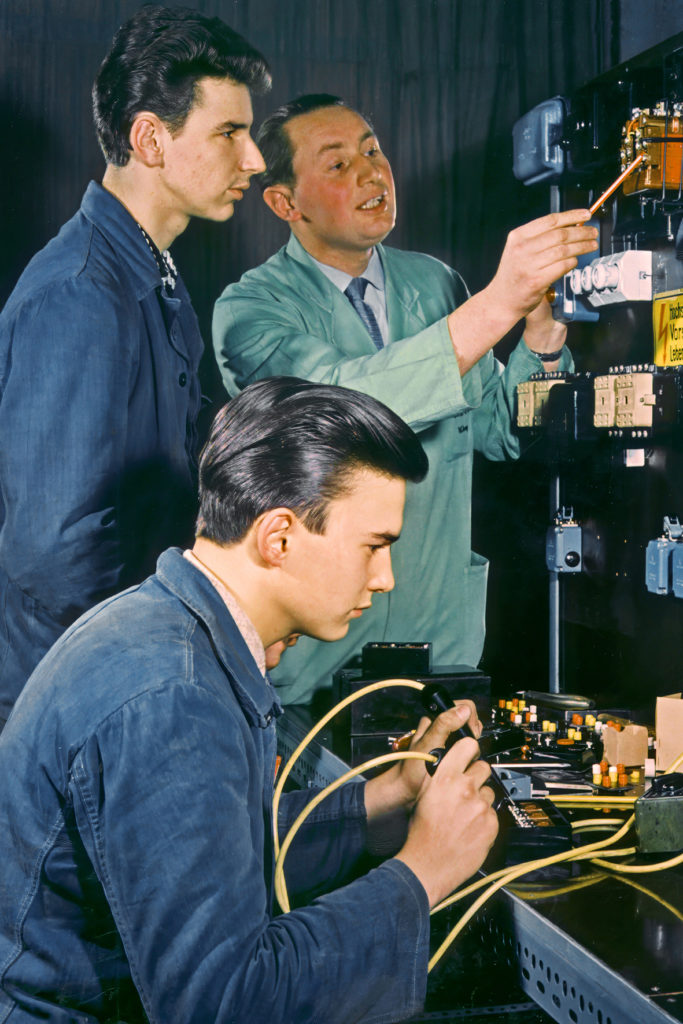

The 21-year-old confidently continues a long tradition. In 1865, the first Opel apprentice begins: Georg Klingelhöfer. His earns three Kreuzer for twelve hours of work – every day. His boss is Adam Opel. The tasks: sweeping, painting, collecting payments. The young Klingelhöfer is skilled – and more efficient at following up on invoices than the company founder. What began with an apprenticeship contract sealed with a handshake 160 years ago is now an institution: More than 27,000 young people have completed an apprenticeship at Opel to date.

“Training is not a satellite, but an integral part of the company. Our pipeline for talent.”

– Head of Training Maik Giess –

The training spectrum currently ranges from industrial mechanics to IT specialists, from firefighters to high-tech experts for electromobility. Particularly in demand: dual training with a university degree. They now account for half of the 170 annual places in Rüsselsheim, Eisenach, Kaiserslautern and Bochum – and attract talent from all over the country. And rightly so: Opel has just won the award “Dual Study: Germany’s Top Trainer” – with full points as the industry winner. “This is the benchmark in the automotive industry,” says training manager Maik Giess.

Globally in demand

The training manager also recently received a delegation from Canada. After all, the two-track training “Made in Germany” is considered the gold standard worldwide. Theory at vocational school, practical experience in the company – this is how skilled workers are created who think and get involved. Opel has honed this diamond for decades. Many nationwide training standards, for example for automotive mechatronics technicians, bear the signature from Rüsselsheim. An important, additional pillar in the company is the training centre, the first point of contact for many trainees. 37 instructors teach the basics of the respective subject area here. “Our training is not a satellite,” emphasises Maik Giess. “It is part of the company. Our pipeline for talent.”

From workbench to plant manager

At the main plant alone, around 80 percent of the employees learnt their trade at Opel – and have stayed. Many have risen through the ranks: managers up to plant managers come from this talent pool. Sebastian Telch and Markus Tauer, now training managers themselves, also once trained at Opel. They say: “Trainees learn more here than the curriculum demands.” An electronics technician is also allowed to weld, a mechatronics engineer can present.

In general, training has changed considerably. No more rigid specifications – projects are created as a team, organised by the trainees themselves. One of them is Muhamet Islami. He wanted to be a teacher – English and philosophy. After five semesters, he pulled the plug and applied at Opel. “The best decision ever,” says the prospective IT specialist. Today he is learning programming languages such as C# and Python. Together with other trainees, he is preparing a presentation for the company party. The eye-opener came when programming the reaction game: “Suddenly everything made sense. The theory of the past months came to life.”

“Joining Opel was the best decision ever.”

– Muhamet Islami, prospective IT specialist –

Tradition with a future:

160 years of training at Opel

Young people have been learning in the company since 1865. Since then, there have been over 27,000.

Self-determined work is a basic principle. “Today’s trainees want to understand what they are doing – and why,” says Sebastian Telch. He is responsible for the metal professions, applicant recruiting, and coordinates cooperation with the universities. The range of training is growing, and new job profiles are being added. For example, when Opel introduced the dual course of study “Applied Computer Science”, no department had asked for it. But the interest grows as the first graduates complete the course. “We are the internal talent factory,” says Markus Tauer, Head of Technical Training. “We anticipate what know-how is needed a few years in advance.” Electromobility and high-voltage training also fall within his area.

Best prospects for the future

Esther Fink comes from Bonn. She moved to Rüsselsheim for the dual study programme. Vocational school, training centre, lectures: “The learning workload is tough,” she says. Nevertheless, she feels comfortable. The cohesion is right. She is also already active in the Rüsselsheim hockey club. Her coach? Works at Opel – in the press shop. “It would be cool if my training took me there,” she says. From the second year of the apprenticeship onwards, the apprentices move on to the specialist departments. It was clear to her that she wanted to work in the automotive industry: “Electromobility, digitalisation, automation – this is where the topics of the future come together.” She has not regretted her decision to join Opel for a second – and the perspectives are good. This year, Opel will once again take on all those who pass their training – for an unlimited period.

May 2025