There is no standstill here. In the final assembly of the Rüsselsheim plant, change is part of everyday life. Facilities are being rebuilt, areas are being relocated, new technologies are being introduced – camera systems, more vertical integration, self-sufficient trolleys. In the middle of it all is the seven-member plant team for production technology. It knows almost every system and every interface – and ensures that they meet the most modern requirements.

“We are also a link between technology and practical application,” says Hans-Jürgen Walther, Equipment Manager and head of the team. The 58-year-old leads a team in which four generations work side by side – and learn from each other. “When differences are valued,” says Walther, “it creates extra punch.” The experienced ones understand old control systems as well as new systems, think solution-oriented and keep an overview. The younger ones bring a fresh perspective, enthusiasm for technology and ideas on automation, data analysis and AI.

„I bring in new ideas, but without the experience of my colleagues, some things would only be theory.“

– Jakob Palm (23), specialist for camera systems and energy optimisation –

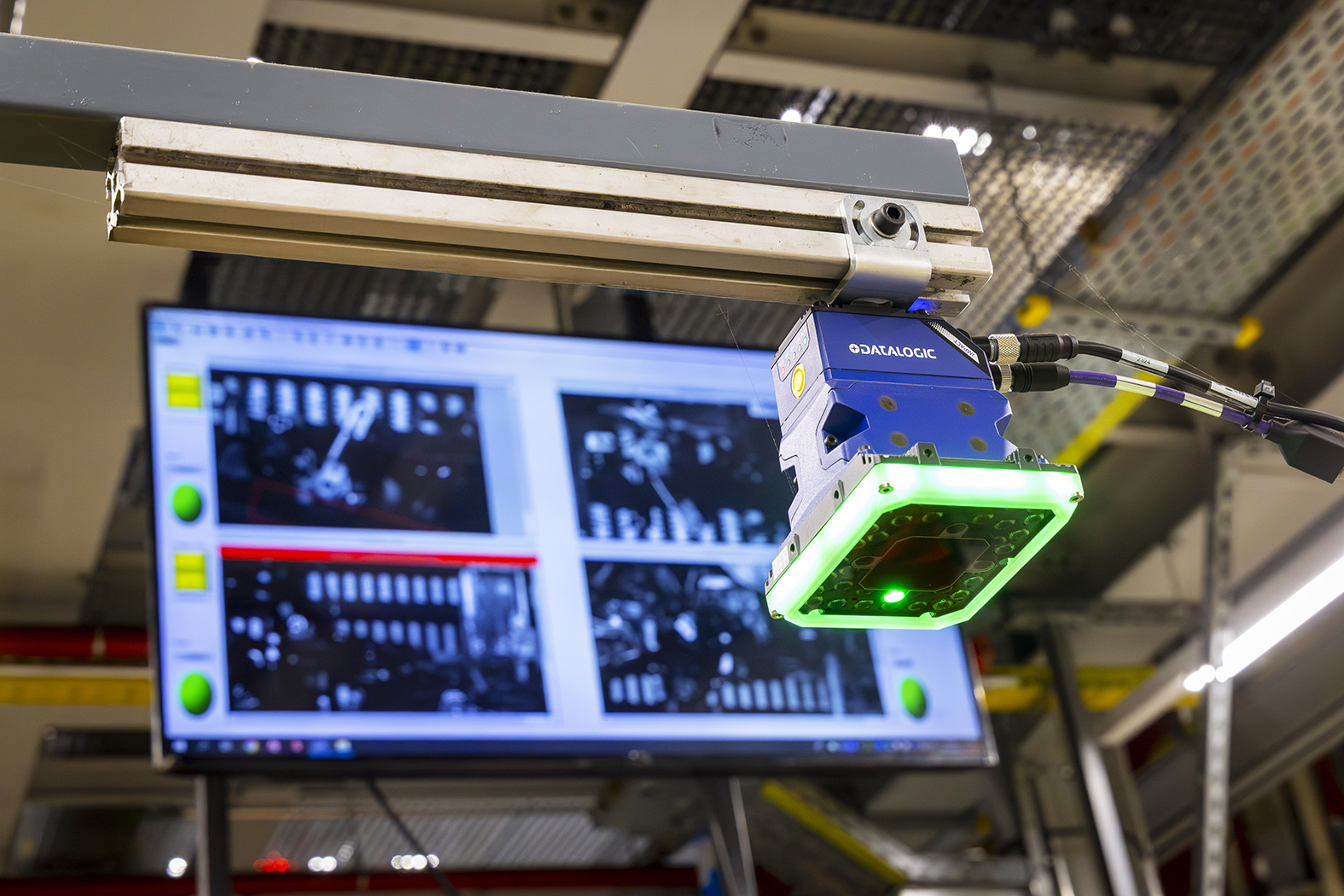

A new camera system has been installed at an assembly station of the substructure. It monitors screw connections on the line. Jakob Palm, 23, was responsible for the installation. He has been part of the team for a year and a half, responsible for energy management and camera systems. “I bring in new ideas, but without the experience of my colleagues, some things would only be theory,” he says. “They know what works in practice – and what doesn’t.” He looks at Mathias Fenzl, 55, who has been with the company for 39 years. “Many systems and interfaces in the plant have grown over decades. If you don’t know how they came about, understanding them can be hard,” says Fenzl. Together, they implemented the camera system.

Palm was also able to count on his colleague’s knowledge during the demolition of a disused cavity preservation unit – 80 metres long, 15 wide, 7 high. „Mathias knows what special features have to be taken into account.“ Conversely, Fenzl appreciates the younger’s zest for action: „He gets things rolling. Even if initially things do not go as planned – that’s what the team thrives on.“ There are no mentoring programmes here. Experience and innovation simply work hand in hand.

„When differences are valued, it creates an additional punch.“

– Hans-Jürgen Walther (58), Equipment Manager –

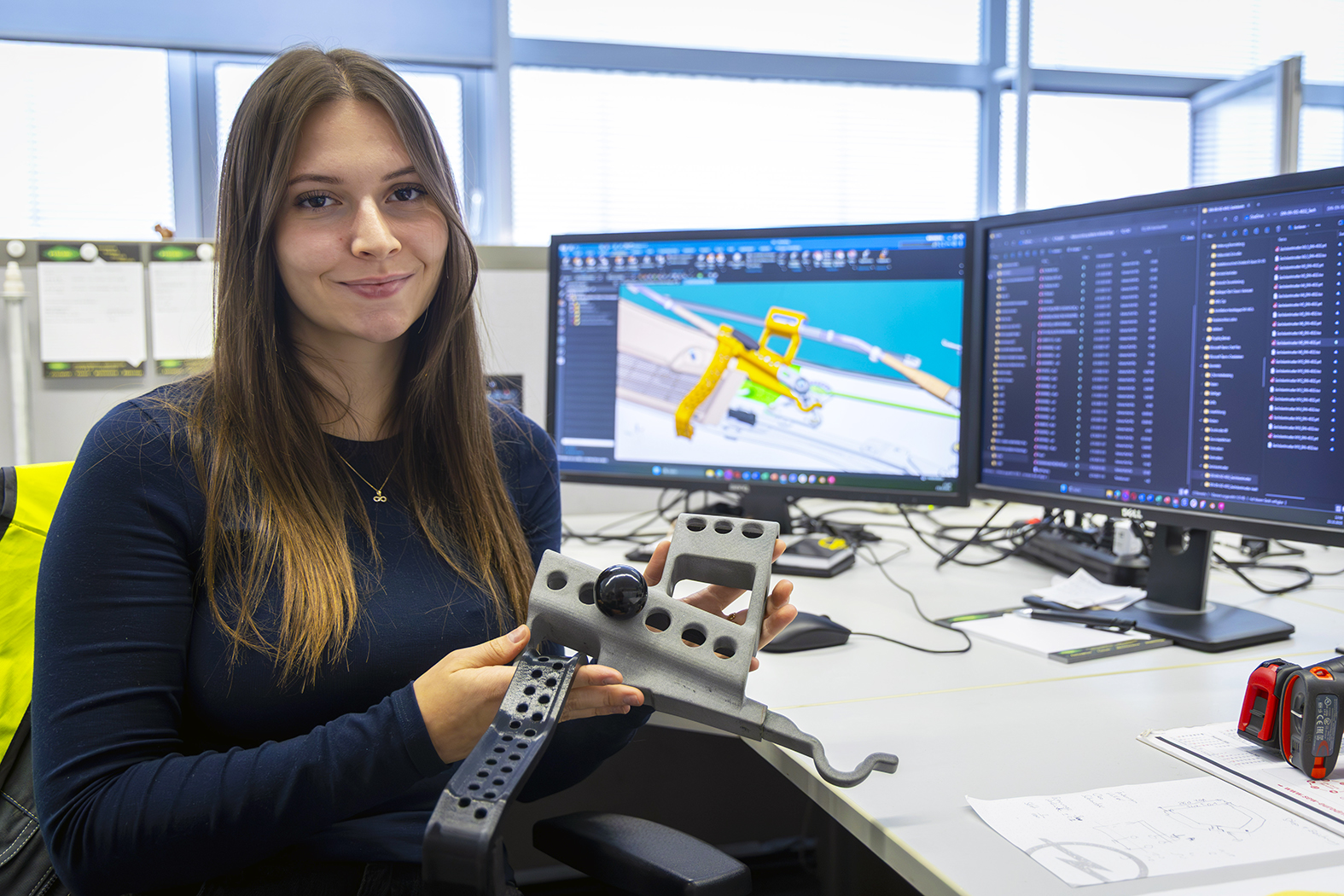

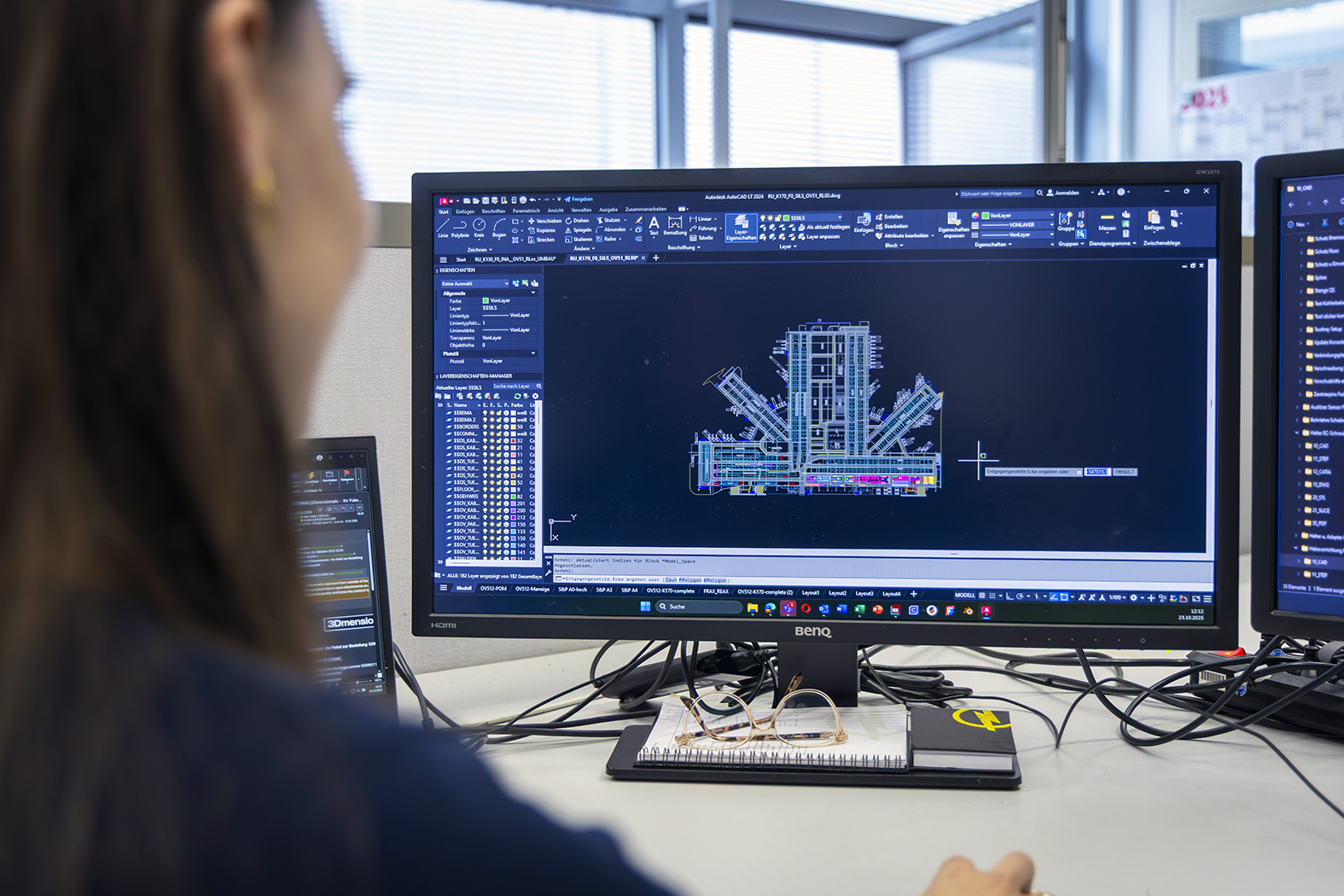

Mia Öffler, 20 years old, is the youngest in the team. She brings in completely new skills. As a trained product designer, she has mastered 3D printing and works with design programs. Her digital plant layouts are in demand when systems move, or new stations are created. She also uses the 3D printer to produce auxiliary tools – such as gauges for windshield wiper installation. “I can implement ideas on my own responsibility,” she says, “and get immediate feedback on whether it has proven itself in practice.” For her, this is hands-on learning: high-tech and craftsmanship, screen and workshop.

„I can implement ideas on my own responsibility – and get immediate feedback as to whether it has proven itself in practice.“

– Mia Öffler (20), Design Engineer –

In general, the team members can be found wherever innovations find their way into production. Everyone has their specialty. Rene Dressler, 30, is responsible for the facilities of the Battery Shop, where the batteries for the Opel Astra Electric, for example, have been assembled since 2022. Matthias Wink, 43, is the master of the filling systems, in which coolants for high-voltage batteries and inverters circulate today in addition to transmission oil. Johann Schreder, 34, on the other hand, orchestrates the automated system for window installation: five robots that place the front and rear windows in the vehicle – including the bonding process.

Time and again, it has been shown that many years of know-how are indispensable. “I benefit immensely from Hans-Jürgen’s experience – he helped build up the Battery Shop,” emphasises Rene Dressler, who has been with the team for a year. Matthias Wink is also the one in the team who drives the preparation of the CE declarations to the point of signature – the certification that conversions are safe and in accordance with standards. He slowly sheds his initial scepticism about the fact that young colleagues first ask AI when they have problems. Wink smiles: “Sometimes amazingly good ideas come out of it.”

„Working here is not desk engineering – we are on site, measuring, testing, screwing, programming.“

– Johann Schreder (34), Trim specialist for adhesive technology –

What unites them all is the fascination for automotive production. „Working here,“ says Johann Schreder, „is not desk engineering – we are on site, measuring, testing, screwing and programming.“ It gets particularly intense when others go on holiday: during the factory holidays, when the production lines are at a standstill. Then the team runs at full speed – precise, concentrated, well-rehearsed like clockwork. „It’s more like a family,“ says Hans-Jürgen Walther. A family in which each generation plays its own role: some with decades of experience, others with digital ideas and a fresh perspective. What unites them is pride in what they create together – systems that run reliably and processes that enable the future.

November 2025