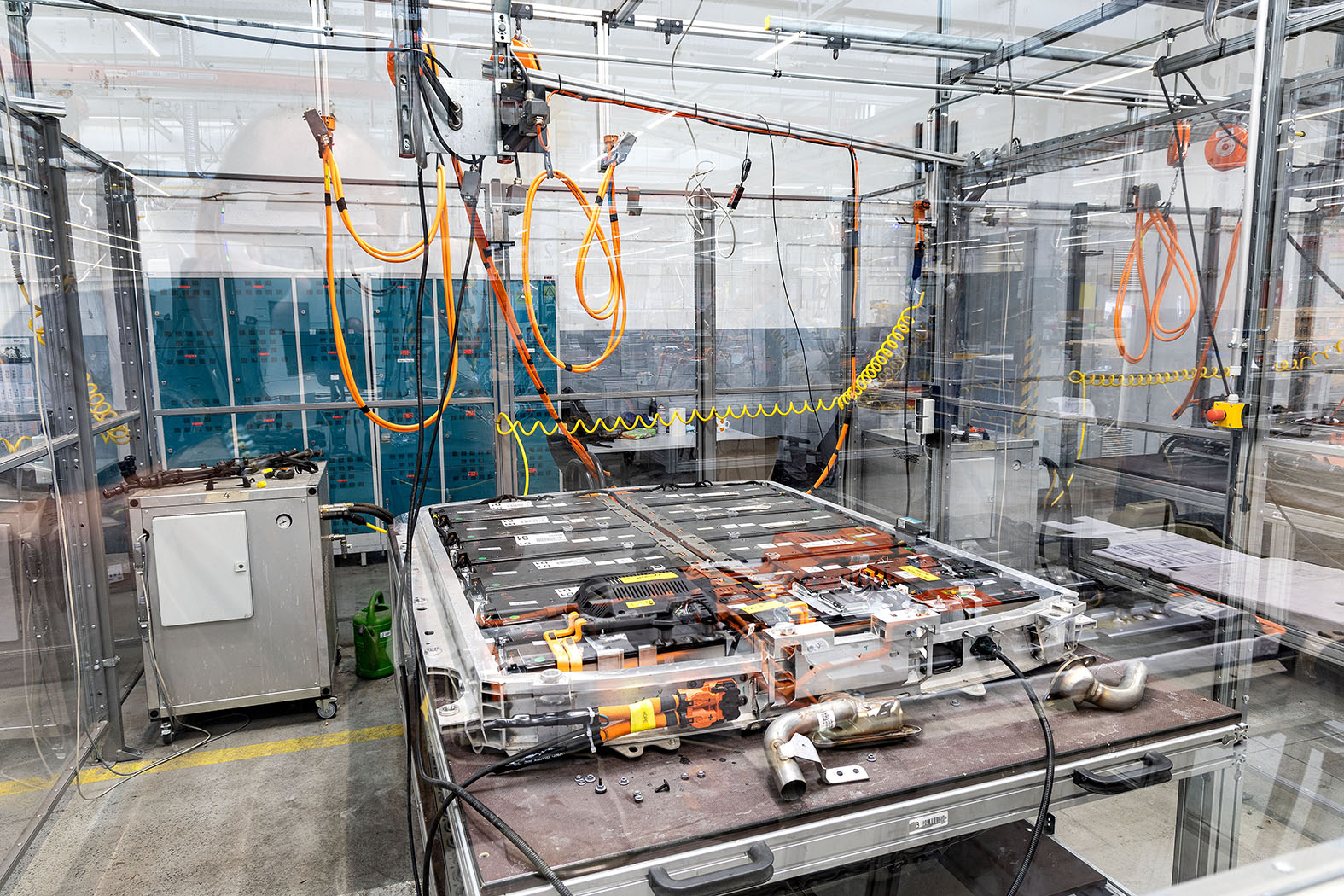

A shielded cell, cables coming out of the ceiling. „This is our high-tech clinic for batteries,“ says Markus Grassmuck, head of the Battery Refurbishment Centre (BRC) in Rüsselsheim. This is where repairs are carried out. A detailed analysis shows what exactly is defective – cell damage, electronics problem or software error. The aim is to repair the lithium-ion battery and make it usable again. In the middle of the factory premises, the centre offers state-of-the-art technology on 1,000 square metres.

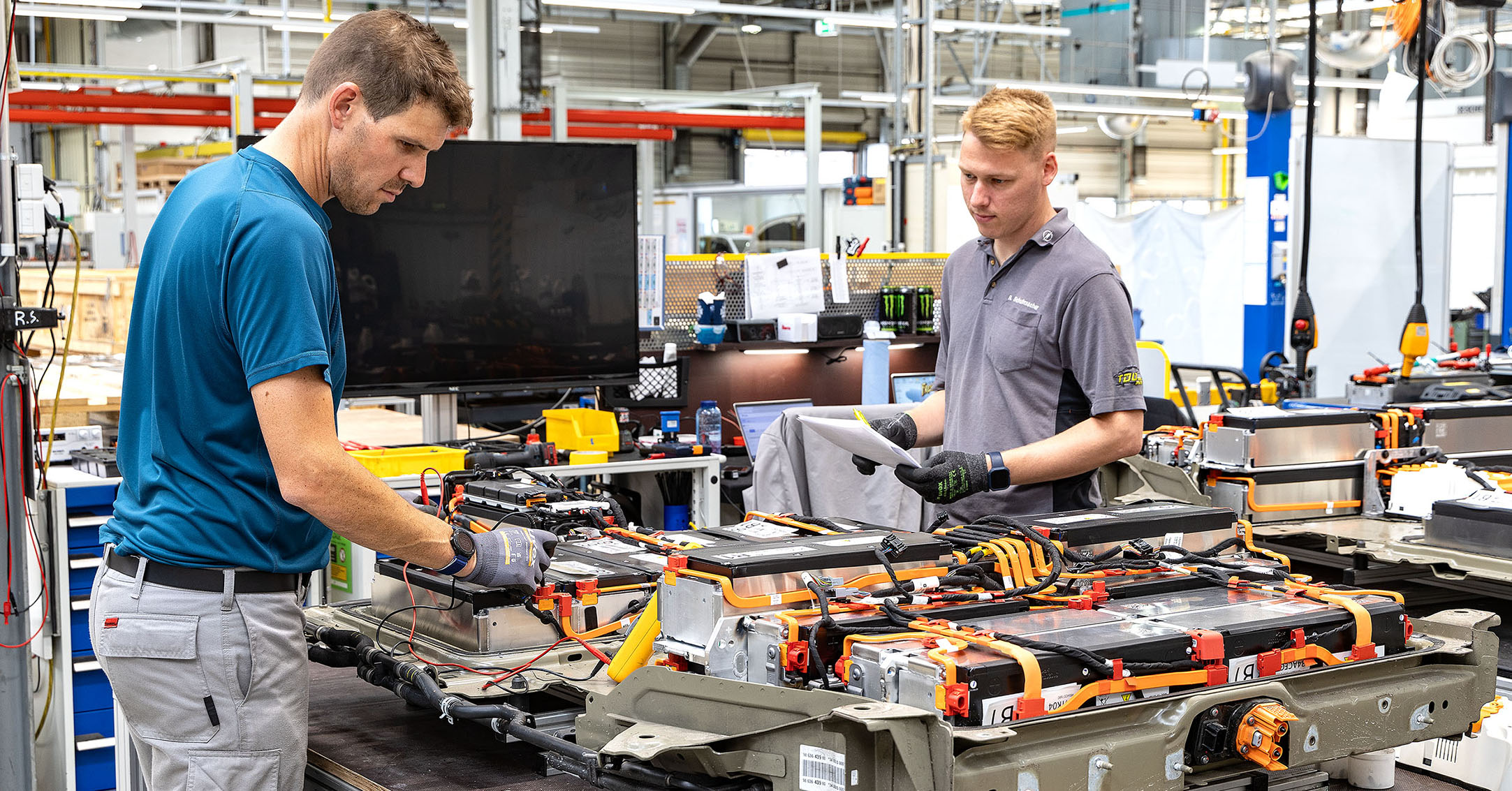

In the center – which is run by Opel Special Vehicles – defective batteries from vehicles of all Stellantis brands are opened, checked, repaired and sealed again. In a well-rehearsed process. It all started in 2011: two employees, one battery type, one model – the Opel Ampera. Today, Grassmuck’s team looks after batteries for a growing electric fleet: from Opel and Peugeot to Fiat, DS or Jeep. Energy storage systems from all over Europe come here – by freight forwarder from the central warehouse in Vesoul, France.

„Diagnosis, repair, test cycles, up-to-date software – we ensure that batteries get a second life.“

– Markus Grassmuck –

Battery failures are very rare. And if happens, the team in Rüsselsheim finds and fixes errors. „Even those who live on the Faroe Islands get their electric car repaired quickly,“ says Grassmuck. The path is clearly defined: the workshop reports a fault. The battery goes out, an equivalent one comes in – often even in better condition than the old one. The defective specimen is sent to Rüsselsheim, where it is restored and then goes back to Vesoul – ready for the next mission. A cycle that works. Because it is precisely organised. And because specialists work in the M55, all with high-voltage Level 5 training – the highest safety standard for working on open batteries.

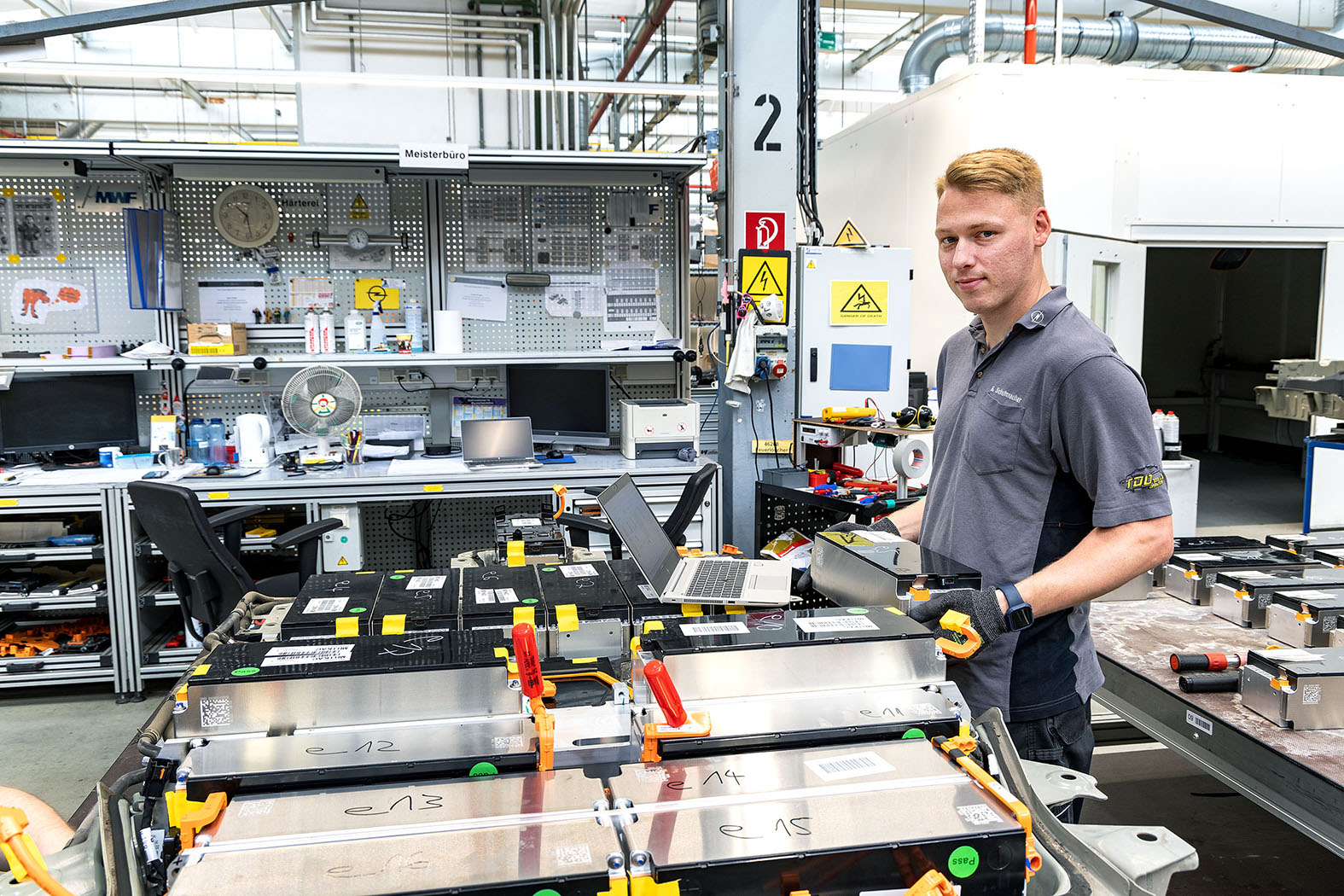

The real mistake, says Grassmuck, is usually well hidden. Error codes from the workshop, but also your own measured values are often only indications – symptoms, not diagnoses. „We are getting a detailed picture,“ he explains. A lot of experience is required. The battery is opened, tested, researched: Is it the modules? The control units? A hairline crack? A blown fuse? Or just a cell that is weaker than the rest? If a module consisting of several cells has to be replaced, it goes to the ‘wine cellar’ – that’s what they call the warehouse here. Modules of different ‘maturity levels’ are stored here. After all, a battery is a sensitive system. New modules must match the state of charge and capacity of the old ones.

„Even customers who live on the Faroe Islands can get their electric car repaired quickly – thanks to the well-established cycle.“

– Markus Grassmuck –

Guaranteed performance

Like all Stellantis brands, Opel offers a warranty of 8 years or 160,000 km on the batteries of its electric models, whichever comes first. This warranty applies to at least 70 percent of the battery’s original charging capacity. The Rüsselsheim-based brand also offers a free battery capacity test as part of regular maintenance. A battery capacity certificate confirming the vehicle’s battery charge capacity makes it easier to resell.

Modern high-voltage batteries are much more durable than once assumed – a result of modern battery management systems. They protect the batteries from overheating, deep discharge and other harmful influences. Practical experience at the BRC shows: „Even after several hundred thousand kilometres, batteries still have a large part of their original capacity on average,“ says Grassmuck. Around 20 percent of the capacity in Hall M55 is currently accounted for by batteries, which are repaired on site and then returned directly to the customers. The vehicles arrive in full – from workshops within a radius of up to 300 kilometres.

Sustainable battery logistics

However, most of the work relates to the exchange processes, i.e. those removed batteries that are sent via the central warehouse in Vesoul. Still. The perspective goal is to repair closer to the workshops – with decentralised repair centres across Europe. Today there are 20 of them. There are to be more, and the electromobility offensive is underway. In the meantime, Stellantis has opened a second Battery Refurbishment Centre in Turin. Batteries for southern Europe go there, batteries from northern Europe go to Rüsselsheim – logistically efficient and environmentally conscious.

Even a module that is no longer suitable for vehicles but still supplies enough energy is given a new life. For example, as a stationary storage system. The tour of the battery clinic shows how much high-tech, dedication and know-how go into the heart of electromobility, which is not a black box – but repairable. Almost always. At the end, a repaired battery leaves the hall in a wooden box. Sealed, tested, fully charged – ready its their second life.

August 2025