- Überflieger: Marijan Griebel zeigte auch beim EM-Finale das enorme Potenzial des Opel ADAM R2 auf.

![]()

Here’s a breakdown of the six steps

taken by the Opel engineers in transforming

the stock unit into a championship-quality racing engine.

![]()

Starting off

with a stock production engine

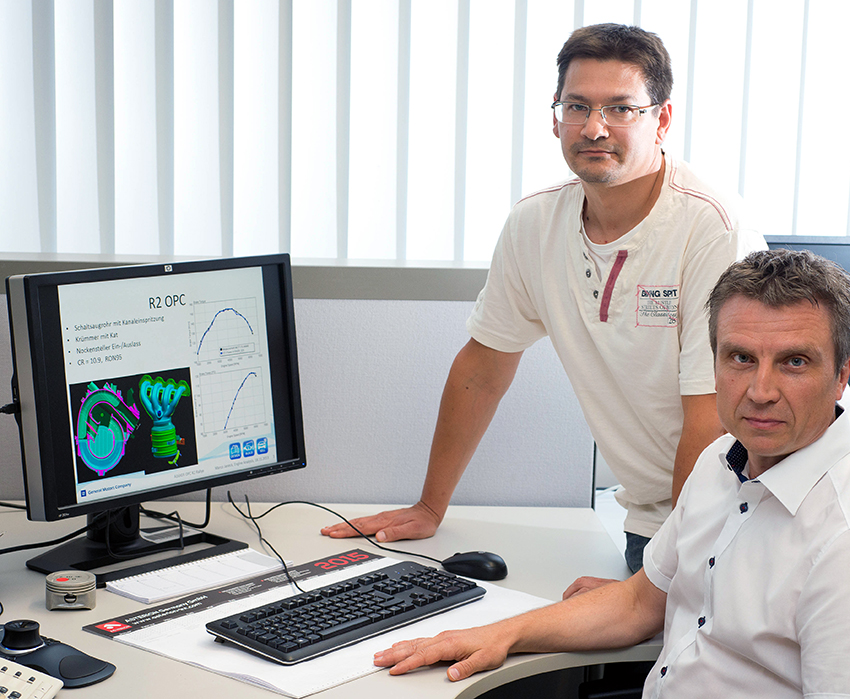

He prevented the ADAM from spending countless hours on the test rig and testing on the track: Dr. Oliver Scherf, who heads up the Engine Analysis Department at the ITEZ in Rüsselsheim.

For a standard production engine, hitting 8,200 rpm would be quite a feat. But that is just what the A16XER racing engine does, the very same unit that helped earn the ADAM, not to mention its young drivers, early victory in the European Rally Championship. The engineers and developers painstakingly worked on the 1.6-liter four-cylinder engine to boost its output from the original 115 hp it put out in the production version to a mighty 190 hp. This added performance was all made possible thanks to computer simulations. Instead of sticking solely to a regiment of hours on the test rig and testing on the track, virtual simulations were also performed on the engine. “First off, we had to create a virtual model of the engine itself,” says Dr. Oliver Scherf, who heads up the Engine Analysis Department at the ITEZ in Rüsselsheim.

![]()

Modifications á la OPC

But before the simulations could begin, the OPC project engineers went to work on the production engine. They performed a number of modifications to the stock unit to increase output and durability to ensure it would be able to meet the extreme conditions it would face in rally racing. The intake manifold, which was already optimized for the production version of the engine using simulations, was given a further go-over by the OPC project engineers who were working within the limits established by the FIA regulations. ‘Sharper’ camshafts increased valve actuation speeds. And because the air that comes in must also be able to flow out again as freely and unobstructedly as possible, the ADAM was fitted with a brand-new high-performance exhaust system.

Tweaking these parts helped improve the flow of air within the engine and pressure wave patterns in the intake manifold, optimize how the exhaust unit works within the overall system, and boost the engine’s output at higher rpms. The end result is more fuel and air being delivered to the cylinders. Other modifications, all done in accordance with the strict FIA regulations for the R2 racing category, were made to the air filter, high-performance pistons, water pump, and alternator. In addition, high-grade 98-octane gas was also used. Once this was done, all these parts had to be integrated into the simulation model to ensure the data collected when running the simulation would accurately reflect the readings that would be recorded on the actual engine.

The engine specialists at Spiess in Ditzingen, who’ve worked for years as a development partner of Opel and OPC, were given first shot at working their magic to boost performance based on their experience. The results of their efforts yielded roughly 95 percent of the current rally engine’s output.

![]()

“The simulation allowed us to squeeze

almost 10 horsepower more out of the engine.”

— Marco Janeck —

verantwortlicher für Ladungswechsel-Optimierung

![]()

Virtual simulations

They helped to improve the performance ant the durability of the engine: Paul Bittner (in the front) and Marco Janeck.

This engine served as the final simulation model, which allowed a wide range of valve actuation speeds and exhaust system designs to be tested within a short space of time. The optimum parameters were found, helping deliver that extra added performance out of the engine that ultimately proved decisive. After all the calculations were completed, the racing engine was put back together. The readings taken on the test rig confirmed the gain in output predicted during the simulation. The A16XER generates 190 hp at around 8,200 rpm. Marco Janeck, who was tasked with improving the gas exchange cycle, is satisfied with the results. “The simulation allowed us to squeeze almost 10 horsepower more out of the engine.”

![]()

Masterful: ERC Junior champion Emil Bergkvist on his way to third season victory.

A pinch of toughness

Marco Janeck’s colleague Paul Bittner did a series of simulations to help improve the engine in another area: durability. This, along with more horsepower at higher rpms, is a crucial factor in determining success in rally car racing and in motor sports in general. A special program for measuring elastohydraulic lubrication was used to test various connecting rod bearings in terms of their suitability for use in racing, allowing the one most capable of working under the harshest conditions to be selected beforehand. Here, as elsewhere, the results from the simulation were backed up by trials on the performance testing station at Spiess and testing out on the track against a competitor’s vehicle.

![]()

Strong comeback: Opel celebrated first European championship title in 33 years with Emil Bergkvist and the ADAM R2.

To be on top, feels very good.

No time for the green idyll: The ADAM roars through a path in the woods.

![]()

Materials put to the test

Materials and parts were subject to a battery of general tests all designed to improve overall durability. This work was performed by Dr. Baumgart from GME Test Labs & Material/Metallurgy Engineering. The results of the tests showed that basic components like the crank shaft and connecting rods from the production engine were more than able to meet the more demanding conditions to be found on the race track.

![]()

Providing the optimum conditions

for championship success

This is what winners look like: Emil Bergkvist and Joakim Sjöberg at ceremony in Zlín.

Improvements made on the computer helped significantly reduce the number of hours spent on the test rig, keeping project costs relatively low. The Opel drivers were more than happy with the results at the six races that make up the European Rally Championship. The combination of more horsepower and improved durability allowed them to take the title. Next season is right around the corner, but now is the time to celebrate. Dr. Oliver Scherf and his colleague Peter Rühl, project engineer for engines at OPC and Opel Motorsport, can also be proud of what they have achieved, given the limited amount of time they had to work with. It all goes to show just what the development team in Rüsselsheim is capable of. We also gained insight into just how tough Opel’s production engines are – and simulations made this all possible.

![]()

Top spot thanks to R2 power

![]()

A flat tire is all that stood between a one-two finish. Marijan Griebel and Stefan Clemens from the Opel factory team suffered that fate in the final race of the European Junior Rally Championship, preventing them from taking second place in the final race (if not first) and, with it, second spot in the series for the ADAM R2. Emil Bergkvist and Joakim Sjöberg, who took the championship crown after four of six races, had already secured first. Despite claiming the title earlier in the series, they still went on to win the final race in Zlín in the Czech Republic.

Second place in the rally went to an ADAM R2 nonetheless. Poland’s Aleks Zaward and France’s Cathy Derousseaux crossed the finish line just behind the European champions in a R2 model they retuned themselves. And even if the ADAM didn’t earn second spot in the overall standings, it would still be hard to match what it has accomplished in the series.

The R2 category, created by the Federation Internationale de l’Automobile (FIA), permits certain modifications to be made to production models within clearly defined limits. One of the modifications made to the ADAM R2 involved installing a roll cage designed according to these rules.

Proud boss: Opel Motorsport-Director Jörg Schrott with the winners Bergkvist (l.) and Sjöberg.

The car tips the scale at 1,030 kilograms. The steering system, rear axle, engine mount, and sequential gearbox are all more or less the same as the ones used in the Opel ADAM Cup model.

The 1.6-liter engine from this model can be found under the hood of the R2 version, though it was given some extra upgrades in line with FIA regulations. Modifications to the camshaft, exhaust manifold, intake system, pistons, and water cooler helped boost output to a hefty 190 horsepower.