The story is known as “The Unplayable Piano”. It happened 47 years ago in the Cologne Opera House when Keith Jarrett sat down at a piano that was actually unplayable: the grand piano was tinny and thin in the upper registers, the black keys were stuck, the pedals did not work, the instrument was too small for the room. The American jazz pianist nevertheless played the concert for the audience of 1,400: he adapted his playing to the possibilities of the piano, avoided the higher registers, built rolling bass riffs into his playing, the result was a performance full of creativity and emotion – the audience and the critics were thrilled.

Exploring creative spaces

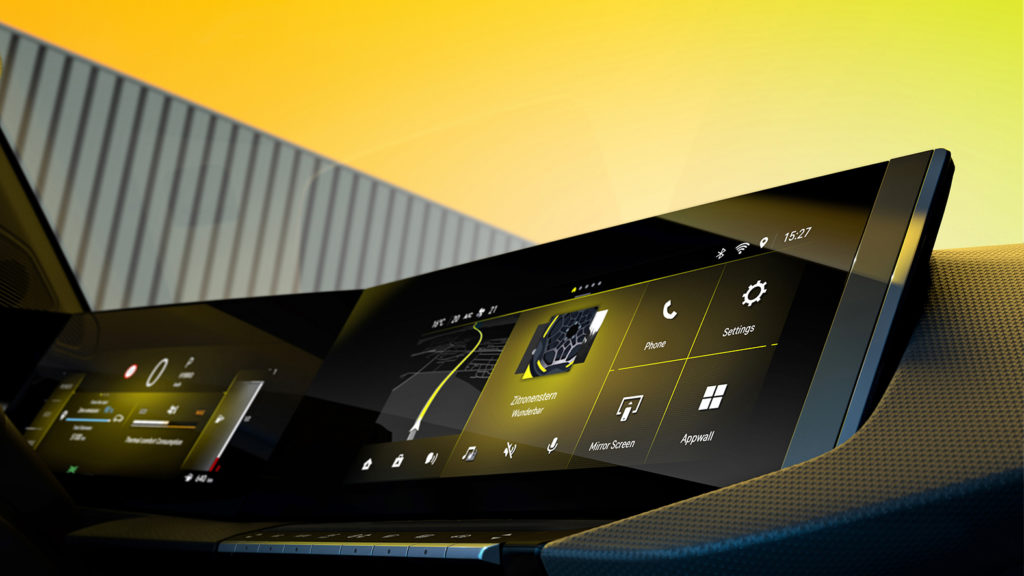

The project team in Rüsselsheim no longer know exactly when the term “The Unplayable Piano” first came up at a meeting or in an email. But it was there to stay. And the element that emerged under the term at Opel’s headquarters is the one about which the Handelsblatt writes: “The Astra offers the real wow effect in the cockpit. The digital world presented there is something you would never have expected from Opel as a volume manufacturer, (…) puristic, clean and high-quality.” The fully digital Opel Pure Panel, the latest generation of human machine interface in the new Astra, is an example of how extraordinary things can be created when a team has the courage and the will to consistently explore new, creative spaces.

– Haiyan Yu, Development Leader Pure Panel Programme Team –

“The name ‚The Unplayable Piano‘ and the story behind it have constantly reminded us that there are always other, creative ways to get where we want to go.”

“The Unplayable Piano” was not just a name, but rather a promise that those responsible made to each other, says Haiyan Yu. “The story behind it has constantly reminded us that there are other, creative ways to get where we want to go,” explains the project leader, who goes by the nickname “Ms Pure Panel“. When the components needed for the cockpit’s ‚bold and pure‘ styling could not be found on the company’s shelves at the beginning, it would have been easy to compromise and adapt the original vision.

Prototype makes an impression

Instead, the team made an appointment with the company management and built a first prototype. Without much effort, simply made of wood, with a glued-on glass plate. The material costs: less than 20 euros. The effect: priceless. “When we came out of the meeting, we had permission to realise the cockpit in exactly the same way,” Haiyan Yu recalls. So the concert was to take place. Now a virtuoso performance was called for. And that’s exactly what the project team delivered.

– Angela Krell, Package Engineer –

“Without the means of virtual simulation, the development of a fully glazed cockpit would not have been possible.”

Angela Krell is a Package Engineer. Her task: to ensure the necessary balance between styling and engineering, to orchestrate the interests of the various departments from electronics to safety, and to keep an eye on the overall package. Together with colleagues from Manufacturing & Engineering, she created the first cockpit superstructures to test the installation of the Pure Panel component and to develop a special installation tool. She also paid special attention to the attribute “fully glazed”. “With regard to reflections, this is a real challenge,” she says and opens a presentation. In it are simulation sequences that illustrate the meticulous detail work. The simulations were carried out and fine-tuned by her colleague Nicloas Böcher: sometimes the driver wears a white T-shirt, sometimes the driver has shiny jewellery on, sometimes the setting sun shines through the rear window.

When the driver wears white

Based on countless simulations, the developers tested a wide variety of materials, tested surface structures and, last but not least, determined the installation angle of the Pure Panel to the exact degree. “Without the means of virtual simulation, the development of a fully glazed cockpit would not have been possible,” says the conceptual designer, who ensured that the simulation results were incorporated into the hardware. To minimise reflections as much as possible, a special shutter-like layer is incorporated into the glass. It also acts like a kind of sun blind. An additional plus: “This allowed us to omit the usual sunshade over the display, which gives the Pure Panel even more high-tech character,” says Angela Krell.

– Joel Lutz, User Experience (UX) –

“The operation is clear and intuitive: maximum comfort with minimum distraction – we call it ‚Detox to the max‘.”

At the same time, Joel Lutz’s team worked on the user experience (UX) aspect of the cockpit. The operation should be clear, unambiguous and intuitive. “Maximum comfort with minimum distraction – we call it ‚Detox to the max‘,” he describes the philosophy. Superfluous information and unnecessary functions – they don’t exist. The fully digital cockpit is slightly curved and turns towards the driver. Some important functions can still be operated via control buttons, the arrangement is reminiscent of a piano. A piano that can be played intuitively. The attention to detail that has gone into the user experience can be seen and heard. The graphics on the screens, for example, were specially designed.

Instruments are in play

The team has also newly developed all the sounds, known as chimes in technical jargon. Like the rhythmic ticking that sounds when you set the indicator, the warning signal when you are not wearing your seat belt. “We did without canned sounds and instead recorded real sounds – played on string and percussion instruments,” says Joel Lutz. And then there are the innovations that have found their way into the cockpit for the first time. The infotainment recognises drivers and even passengers based on their smartphones. So different people can activate their individual settings with a touch on the widescreen. “Hey Opel” – two words are all it takes, and the Pure Panel in the Astra is all ears to what the driver and passengers want. The new natural voice recognition works fully networked like the entire latest-generation infotainment system.

– Monika Krämer, Supplier Management –

“Customers never get to see one of the most ambitious components of the Pure Panel: The supporting structure made of magnesium.“

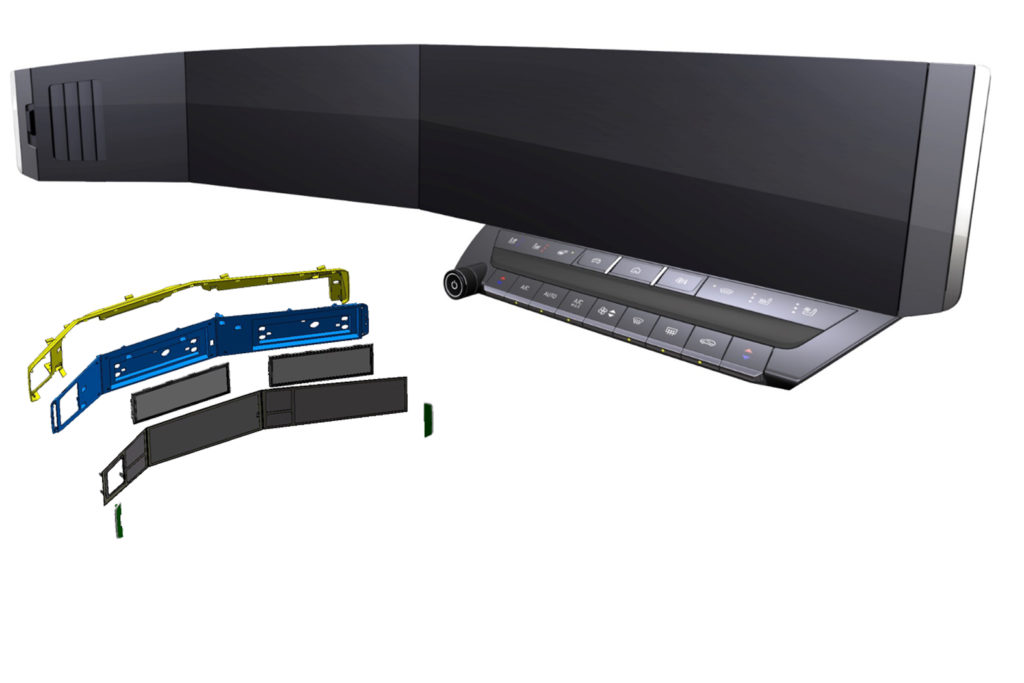

And the Pure Panel, from an engineering point of view, is not just two 10-inch monitors connected behind real glass, but a highly complex component integrated into the car – from climate/heating to electronics and hardware. Even the ventilation nozzle for the driver is integrated into the seamless glass. Accordingly, the work of the suppliers had to be meticulously coordinated. Responsible for this: Monika Krämer. “Customers don’t even get to see the most ambitious component of the Pure Panel: the supporting structure,” says the supplier manager of the development team.

Carefully composed package

It is the central, load-bearing component of the cockpit. Here, too, the specifications were demanding. The heaviest component of the cockpit had to be light and at the same time stable. “That’s why we decided on magnesium. A raw material that is three times lighter than steel, one-and-a-half times lighter than aluminium and at the same time has high rigidity,” says Monika Krämer. The available installation space – it is a carefully composed package.

– Matthias Röthel,

Perfection in Vehicle Integration –

“The Pure Panel is only perfect when the colleagues in manufacturing can also install it perfectly.”

The cockpit components manufactured by the suppliers all end up in one place sooner or later: in K111, the so-called Mapiex workshop in the middle of the Rüsselsheim plant premises. Here, not far from the Astra production line, a team ensures that the components can be fitted with dimensional accuracy. The head of the department, Matthias Röthel, personally took care of the sophisticated cockpit. The cockpit, including the centre console, is set up in front of him on a test bench. “I’ve installed and removed pretty much every component 500 times – at least,” he says. “It’s only perfect if the colleagues in manufacturing can also install it perfectly.” Gap dimensions are a key factor, but so are the forces required to unite the components. And on the shelf behind Matthias Röthel stands the object that set the development in motion: the prototype made of wood and glass that the team presented to the company management. That was two years ago.

Masterpiece from Rüsselsheim

And how did the story of “The Unplayable Piano” from the Cologne Opera, which was the inspiration for the Rüsselsheim project, turn out? It is still known today because the recording made that evening brought Keith Jarrett his big breakthrough. The album “The Köln Concert” sold 3.5 million copies. To this day, it is the best-selling solo jazz album ever. “We have – like Keith Jarrett back then – left the usual paths of thinking and acting. Again and again,” says Haiyan Yu. That takes courage and self-confidence and doesn’t always automatically guarantee immediate success: “But it gives life to new creative space and, as a result, an extraordinary experience in the vehicle cockpit that hopefully many, many customers will experience in the new Astra.” The masterpiece composed in Rüsselsheim can now be experienced live in many places – the new Astra has been in series production at Opel’s headquarters since mid-February.

February 2022